Reliability, Availability & Maintainability (RAM)

MES Ltd offer a comprehensive package of Reliability, Asset Management and Life-Cycle Cost consulting services to the Oil and Gas and Wind Farm industries. We have a team of RAM engineers with many of years of experience in carrying out RAM studies for some of the largest organisations in the world on multi-million dollar projects.

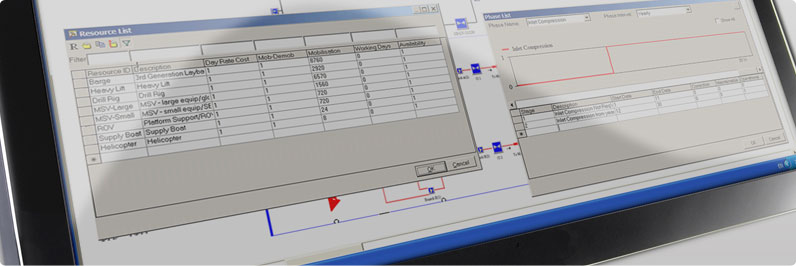

MES Ltd have sophisticated in-house software tools which have been developed over a number of years and used to perform a number of RAM studies, including:

RAM (Logistics)

- Tanker export modeling including weather impact.

- Real time animation.

- Buffer Storage modeling.

- Reliability Centered Maintenance (RCM).

- Risk Based Maintenance.

RAM (Oil & Gas)

- Assess the performance of complex oil and gas related systems.

- Evaluation of annual Production Availability and other Performance related parameters.

- Application of various operating policies (e.g. Makeup, Flaring, Line Packing and Bulk Storage etc.), Production Phasing, multiple sources and production profiles, early life failures (using the Bath Tub Curve), and Multiple Sales Quotas.

- Driver selection studies.

- Spares optimization.

- High Integrity Pressure Protection System (HIPPS) Studies.

- Safety Integrity Level (SIL) analysis and verification studies.

- Life cycle costing analysis.

RAM (Wind Farm)

- Model performance of Wind Farms and their associated transmission distribution network.

- Assess the impact on Availability (or Annual Energy Production) caused by access restrictions due to weather and other events.

- Identify operational losses due to downtime, and recommend the level of system redundancy required to mitigate the effects of system failure.

- The modeling features include wind/wave data (e.g. the maximum wave height for accessing Wind Turbine Generators), number of crews, crew shift systems (e.g. night working), number of vessels and any other travel restrictions.