PLASMA (Oil and Gas Industry)

General:-

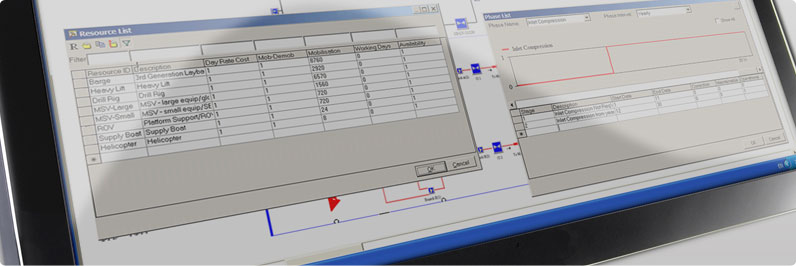

- Powerful visual interface with simple drag and drop techniques;

- Deterministic and stochastic techniques;

- Series, Active Redundancy (Full, Partial or Conditional) and Standby Redundancy (Identical units or Different units);

- Control of the sizing of parallel units as a function of time (i.e. varying levels of effective redundancy);

- Load Sharing;

- Production Availability i.e. throughput estimation;

- System or component importance ranking; It enables the user to identify the systems or components that are the main contributors to Production Unavailability, Total Down Time, Cost, Safety Criticality, Asset Criticality and Environmental Criticality;

- Modelling complex systems using multiple layers of RBDs and PFDs.

Maintenance modelling:-

- Unscheduled, Delayed (e.g. seasonal);

- Maintenance duration and restoration factors;

- Maintenance policies;

- Planned;

- Condition monitoring;

- Opportunity maintenance;

- Services and utilities;

- Job priority;

- Spare parts pools.

Operating Policies

- Makeup (by boosting);

- prioritised (of product exporting);

- monitoring (of production movements);

- Deferred Production;

- Flaring Operations;

- Load Shedding;

- Line packing and

Production Phasing and Transient Data:-

- Control of phasing-in and phasing-out of any part of the logic network;

- Control of the production capacity within any part of the network;

- Control of contract return period (for sales quota make-up) as a function of time;

- Control of branch boost factors as a function of time;

- Control of buffer storage volumes as a function of time;

- Control of export scheduling criteria as a function of time;

- Control of maximum flow in a branch as a function of time;

Life Cycle Scenarios

- Economic Modelling aspects:- CAPEX, OPEX, NPV etc.;

- Performance and asset optimisation.

Logistics

- FPSO and Subsea;

- Tanker Export Modelling:- Transport mode (sea, road or rail), Operations Mode (define whether dealing with export or import), Berth data (dual tanker loading operations);

- Number of shuttle tankers in the fleet, Carrying capacity, Range, Early and Late arrivals etc.;

- Iconic animation (moving ships, etc.);

- Operations details of shuttles;

- Maintenance Vessel;

- Weather Module:- Location (reference to geographical location of shuttle loading facility)

- Seasons (default given for Northern Hemisphere)

- Weather Data Matrix (comprising cumulative probability of nominated wave heights per season and the associated average of occurrence of this range)

Other modelling details

- Interactive construction of Network, Fault Tree or Event Tree diagrams;

- Multiple sources and production profiles;

- Sub-system or pagination facilities for large Network, Fault Tree and Event Tree diagrams;

- Import and export facilities;

- Interface with Excel spreadsheets. Effectively allowing the user to export and import data to and from other spreadsheets;

- Multiple Sales Quotas;

- General failure behaviour of an equipment i.e. bathtub curve.

Fault tree package

Fault tree package RAM Simulator

RAM Simulator Plasma - Oil and Gas

Plasma - Oil and Gas Plasma - Wind (renewable)

Plasma - Wind (renewable)